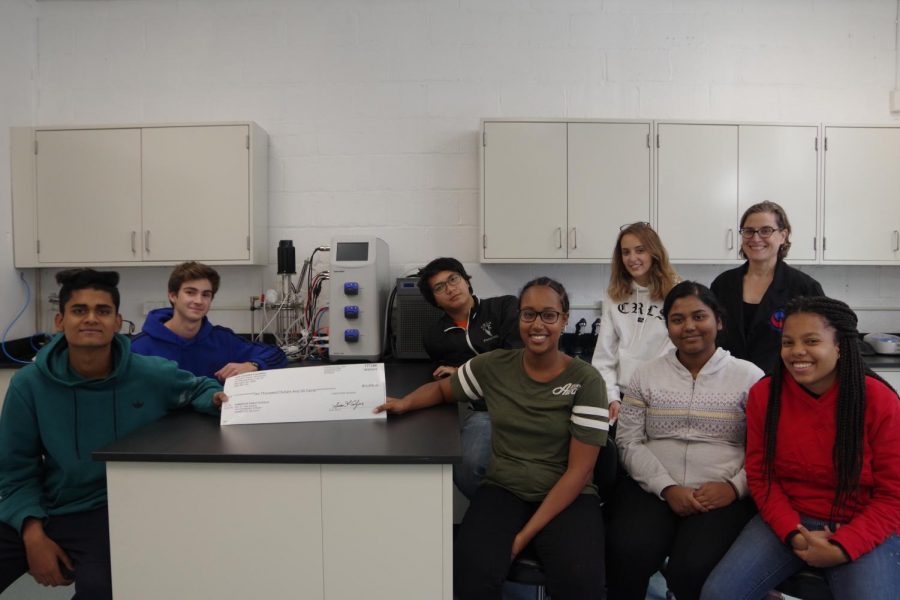

New Equipment at RSTA’s Biotech

Recent funding has allowed the RSTA biotechnology program to improve their labs.

October 30, 2018

RSTA’s biotechnology program has recently installed new equipment which will play a big role in the new curriculum for biomanufacturing and research by students in the field. The program is geared towards students especially drawn to science “who want to do hands-on work and don’t just want to learn about things and hear about things, but to actually do them,” biotechnology teacher Dr. Joan Abrams explained. “It’s a really nice complement to what goes on in the science department.”

“Biomanufacturing is when you want to make drugs that are proteins,” Dr. Abrams explained. “30% of [the drugs that are on the market] are biologics that are protein-based, or they are antibodies that need to be made in cellular factories.” To sum the complex processes up, biomanufacturing is “using little cells as mini-factories to make your protein product.”

The program offers three levels: Level One is one semester, while Level Two takes up two semesters. Once students make it to Level Three, they have a choice between two programs: “You kind of decide if you want to do research and work in a lab doing independent, authentic research, or [if] you want to study this large-scale upstream, downstream processing that is going to get you into the industry.” Dr. Abrams continued, “Literally, after two years [of being in the industry after graduating from CRLS], you’ll be making $55,000 to $60,000 because it has a huge demand [in the job market], it’s highly specialized, and it’s an extremely important function.”

The program has recently been funded by a few large grants, enabling them to improve and add to the contents of the lab. “We’ve had almost $300,000 worth of grants that have come into upgrading the main part of the lab,” Dr. Abrams said. “We have a mammalian cell culture space, … and then across the hall, we have a new biomanufacturing training space.”

Specifically, the lab was funded by the Massachusetts Life Sciences Center. The program has also received grants from the Biogen Foundation, and just a couple weeks ago, they received a $10,000 grant from the VWR Foundation that went to final instruments and supplies. Among the new equipment is the mammalian cell culture space and a biomanufacturing training space complete with a SmartBoard, so classes can be taught in the lab across the hall as well.

According to Dr. Abrams, the new lab allows them to culture up to five liters of cells at a time—much more than they were previously able to.

Cells are first engineered to produce proteins and grown under extremely specific conditions. Next, the cells are harvested and broken open so the protein can be collected and purified. These cells “simulate what’s going on all over the biotech world,” Dr. Abrams explained.

Through the program, CRLS students like senior Nia Abdurezak have gotten opportunities to intern at places such as MIT and the Broad Institute. “Because of this class, I was more ahead than some of the other people that were in the program, because I had experience working in a lab and working with different techniques,” Abdurezak explained. “I would definitely say the hands-on experience is what separates it from other classes in biology, like the AP Biology class here, and that’s what really got me interested in biotech.”

Senior Prachee Mazumder agreed, saying, “I think it’s really great; we get to learn about a lot of lab skills, which helped me to get internships throughout the class.”

The research branch will be available starting next year for twelve seniors—even those who may not have completed Levels One and Two. “We’re going to offer the research-focused course where students will spend the full year [researching],” Dr. Abrams explained. “At the end of it, they’ll have a publication-quality paper, they’ll have presented in different science competitions, and they’ll have a lot of experience. It’s really high-caliber research.”

Dr. Abrams hopes to get principal investigators, the people in charge of the labs and “the really important people in a research environment,” to agree to individually take on a student for this course.

These new changes are exciting to many, including Level Two junior Anaka Landrigan. “We will be getting to do some higher-level techniques that aren’t available in other classes,” Landrigan commented. “It also helps you get a jump start on important skills that are needed in the job industry.”

This piece also appears in our October 2018 edition.